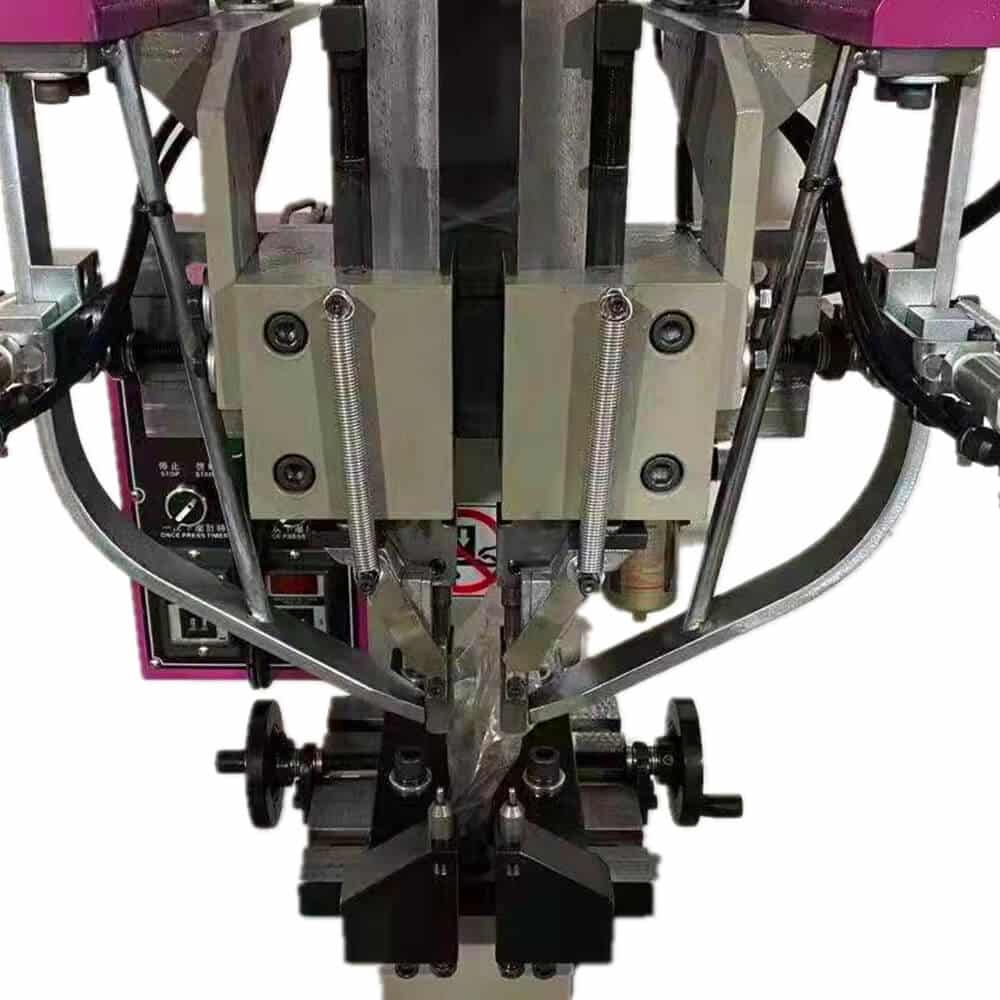

Pneumatic Dual Feeder Riveting Machine

Pneumatic Dual Feeder Riveting Machine is an automatic feeding rivet machine, dual rivet feeders, pneumatic-driven, to reduce noise in the workshop, more economical save energy, it will automatically feed 2 pieces of rivets in one action.

Pneumatic Dual Feeder Riveting Machine RM-D190HP

Pneumatic Dual Feeder Riveting Machine is an automatic feeding rivet machine, dual rivet feeders, pneumatic-driven, to reduce noise in the workshop, more economical and save energy, it will automatically feed 2 pieces of rivets in one action.

Applications

Parameters

- CE Certificate: YES

- Control: Automatic

- Rivets type: Hollow rivets, Semi-tubular rivets, and Solid rivets

- Throat depth: 250mm(Can be enlarged according to needs)

- Throat height: 750mm(Can be enlarged according to needs)

- Rivets diameter: 3-8mm

- Rivets length: 5-20mm, 20-50mm(different toolings for the different lengths of rivets)

- Driven power: Pneumatic driven

- Motor: 140 W

- Voltage&Plug: Customized as per customers’ requirement

- Pneumatic pressure: 3.5-6.5bar

- Dimensions: 500×800×1700 mm/1900mm

- Net Weight: 280 Kgs

Pneumatic Dual Feeder Riveting Machine Specifications

This model is an automatic feeding riveting machine, it has 2 sets of rivet feeders, driven by the pneumatic source. The rivet bulk feeder will select rivets according to rivet body diameter, then send rivets to the rivets feeding channel in the queue, and 2 pieces of rivets will stand by in the clamp. When the operator steps on the foot pedal, the air source will drive the pneumatic cylinder to punch down, and the puncher which connects to the cylinder will press the rivets down. The whole process is automatic, the operator just needs to load the rivets into the feeder in bulk quantity, which will save much time for production.

- Dual feeders, process 2 pcs of rivets together in one action.

- Save labor costs. Automatic feeding rivet for more efficient processing.

- Acceptable for hollow rivets, semi-tubular rivets, and solid rivets.

- Easy operation. Operators just need to load workpieces and step foot pedal.

- Pneumatic driven.

- Lower noise, less than 30dB.

- Safety devises to prevent human injury.

- Energy saves, machine motor is only 140W.

- Take small area, easy maintenance, very easy to replace worn parts by workers.

- 24 months warranty for the machine, 6 months for punchers and dies sets.

Video

Machine Views

Different designing double feeding channel for a small distance in between 2 pieces of rivets.

Upgrade items: vibratory bowl feeder model, with CNC indexing plate.