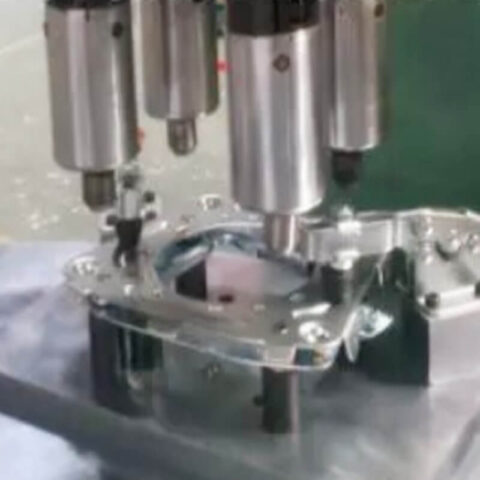

Multi Spindle Head Riveting Machine

Multi Spindle Head Riveting Machine is the multi spindle orbital riveting equipment, which driven by hydraulic or pneumatic power, designed as the vertical type or bench type. This multi spindle head riveting machine perform riveting more than one rivets at the same time.

Multi Spindle Head Riveting Machine

Multi Spindle Head Riveting Machine is the multi spindle orbital riveting equipment, which driven by hydraulic or pneumatic power, designed as the vertical type or bench type. This multi spindle head riveting machine perform riveting more than one rivets at the same time. It adopts the advanced of orbital technology-advanced cold rolling technology. It is applicable to the so many industrial, such as automobile industry, electrical industry, daily use goods industry.

This model of rivet machine is specializing in riveting solid rivets of material iron or steel.

- Roughly adjusting: The orbital head can be lifted up and down by turning the wheel.

- Micro adjusting: The screw cap which equipped with index ruler working for micro adjusting.

The maximum capacity is:

- Solid rivets with diameter 10mm.

- Semi-tubular rivets with diameter 20mm.

The maximum distance adjustment is:

- Minimum distance 32mm.

- Maximum distance 120mm.

Applications

Video

Parameters

- CE Certificate: YES

- Control: Electrical

- Rivets type: Solid rivets, Hollow rivets, Semi-tubular rivets

- Driven power: Hydraulic driven or Pneumatic driven

- Voltage: Customized 100V-240V 1 Phase/380V-415V 3 Phases 50/60 Hz

Notice: Rivet diameter tested by A3 steel material rivets

| Model | RM-B8P | RM-B12P |

| Max. Capacity | Φ3~Φ8mm | Φ3~Φ20mm |

| Max. Riveting Press | 2-10KN | 65KN |

| Stroke | 40mm | 45mm |

| Throat depth | 155mm | 330mm |

| Hydraulic Output | 2~6bar | 10bar |

| Power | 750W | 3.0KW |

| Weight | 155KG | 550KG |

Specifications

Multi Spindle Head Riveting Machine is the latest forming and fastening process which instead of spinning, hammering, pressing, welding, upsetting, the riveting result is a very smooth surface on metal, it will increase much production and save power.

- Increase production and save labor costs. Rivet will be processed within 0.5-3 seconds.

- Electric control units are equipped with digital display time relay and counter for easy operation.

- The best quality of all units on this machine ensures the smooth surface of workpiece and stability of processing.

- Acceptable for hollow rivets, semi-tubular rivets, solid rivets.

- Easy operation. Workers operate the machine by stepping foot pedal.

- Vertical Type, workbench designing, to make worker relaxed and comfortable.

- Hydraulic driven.

- Bearing: The use of best quality bearings, the wear-resistant degree of similar bearings 8-10 times

- Mold adopts alloy steel KD11 material.

- Take small area, easy maintenance, very easy to replace worn parts by workers.

- High productive and economic price.

- Safety devises for preventing human injury.

- 24 months warranty for Multi Spindle Head Riveting Machine, 6 months for riveting tooling.