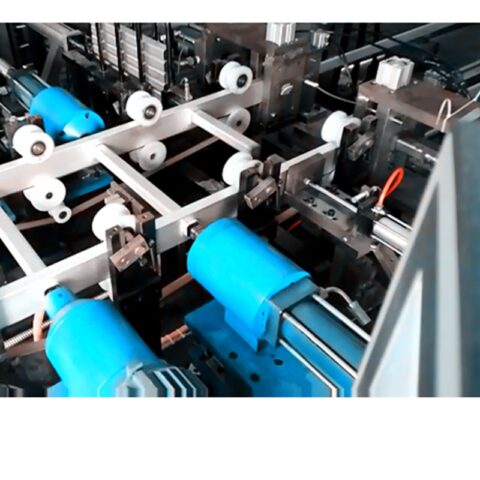

Fully automatic aluminum ladder production line

Fully automatic aluminum ladder production line is a complete solution for ladders. It combines the advantages of reduced cycle times in a single automatic equipment. Steps: 1.Punch the rung holes 2.Rung insertion 3.Rung expanding 4.Rung flaring

Fully automatic aluminum ladder production line RM-923FA

Fully automatic aluminum ladder production line is a complete solution for ladders. The production machine combines the advantages of reduced cycle times together with high output quality, in a single automatic equipment. One worker is enough for producing aluminum ladders. Steps:

- 1.Punch the rung holes

- 2.Rung insertion

- 3.Rung expanding

- 4.Rung flaring, orbital riveting

Applications

Video

Parameters of Fully automatic aluminum ladder production line

- CE Certificate: YES

- Control: CNC, Automatic

- Step rungs distance range: 180-350 mm Customized

- Step rungs width range: 220-650 mm

- Cycle time: Approximately 20 seconds/meter

- Profile length: 1000 up to 6000 mm

- Hydraulic pump output: 16 Mpa

- Voltage: 380-415V 4 Phases 50Hz Customized

- Pneumatic pressure: 2.5-4.0 bar

- Dimensions: 15000×2600×1500 mm

- Net weight: 4923 Kgs

- Available rungs: Square rung, rectangular rung, oval rung, waist circular rung, prismatic rung, etc.

Specifications of Fully automatic aluminum ladder production line

It executes automatically the production of parallel ladders, folding ladder, scaffolding ladder, multi-purpose ladders, platform ladders, extension ladders, industrial ladders, loft ladders etc. It combines the advantages of reduced cycle times together with high output quality, in a single automatic equipment. This production line is a complete solution for ladders. One worker is enough for producing aluminum ladders.

- Fully automatic solution. 1.Punch the rung holes – 2.Rung insertion – 3.Rung expanding – 4.Rung Flaring

- High output quality, to perform high efficient and productive.

- Available for different shapes of step rungs, by replacing customized expanding and flaring tooling.

- Fully adjustable functions for different sizes of ladders. Equipped with automatic holding and feeding device, highest precision controlled by PCL system.

- Continuous operation, to save much labor costs

- Flexibility, Productivity increase, Resource Efficiency, Safety

- Model selection: Manual/Semi-auto/Fully-auto

- PLC control, time setting and pressure adjusting.

- Touch screen, visible digital display, full processes monitoring.

- 24 months warranty for production line, 6 months for punch and dies sets, expanding and flaring tooling.